Digital dental impressions are fast becoming the norm as an increasing number of clinicians and laboratories embrace this newer technology. Some of the benefits of intraoral scanning are obvious, such as speed and accuracy, but there are additional advantages you might not have considered. In this article, we look at digital dental restorations and the digital workflow. Not convinced digital impressions are worth considering?

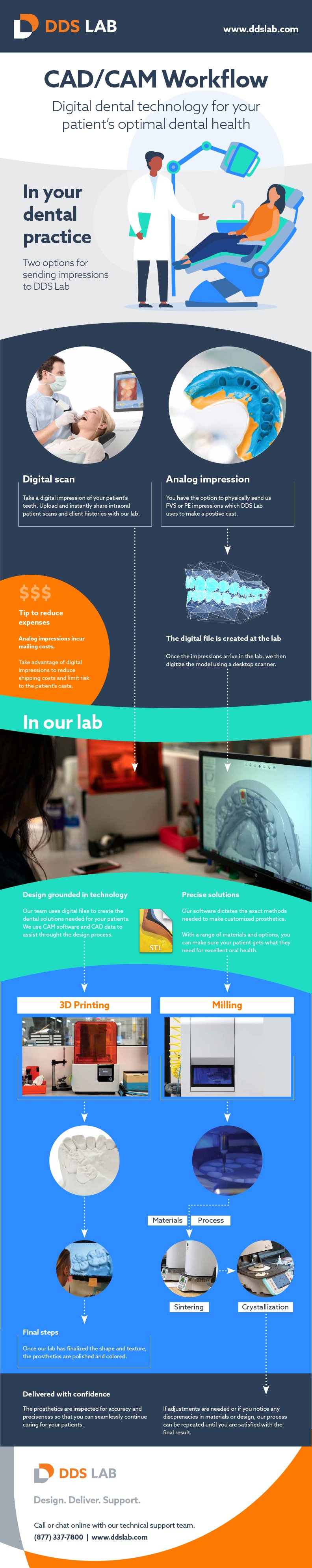

Clearly, the adoption of digital technology is accelerating. Although the technology is complicated, the benefits to your patients and your practice are easy to see. Consider the following workflows:

At your office - Option 1:

Capturing a Digital Impression with an Intraoral Scanner

Using a handheld digital scanner, you can obtain a digital impression of your patient’s teeth and soft tissues.

-

65% of patients find digital impressions more comfortable, and they perceive that treatment is faster too.

-

74% are impressed that their dentist has this technology.

-

85% will tell others about their digital dental experience.

Once a digital impression is captured, the digital file is easily shared with your dental lab, without the need for time-consuming packing and shipping. DDS Lab can begin processing an intraoral scan within minutes of receiving it. A case can be started even before a traditional impression has left the dental office. If necessary, you can call your lab to check the quality of the scan while the patient is still in the chair, eliminating the need for additional appointments due to unsatisfactory impressions.

At your office - Option 2:

Capturing an Accurate Dental Impression with an Analog Impression

An analog impression is obtained using conventional impression trays with alginate or another dental impression material. The impression material must be accurately mixed, and the patient needs to remain still for several minutes - which isn’t easy at the best of times and especially for anyone with a strong gag reflex. Once the impression is removed, it must be checked for accuracy.

Shipping an Analog Impression

Next, the analog impression is disinfected and packaged for shipping. Mailing an analog impression to the dental lab incurs additional costs. Once the lab receives the impression, it is checked and graded, and then it is ready for casting and digitalization.

Inside the dental lab:

CAD Software: Beginning the Process of Fabricating Digital Dental Restorations

DDS Lab’s technicians use the digitized scan of the patient’s mouth to design the replacement prosthetics. These prosthetics may be crowns, bridges, implant components or full dentures. The digital design file (for example an STL file) is then imported to CAM software.

CAM Software: Reading the Digital Design

CAM software interprets the CAD design data, outputting it as machine instructions that are used to control the movements of the hardware creating the prosthetic. The hardware may be a dental mill or printer that turns the virtual design into a physical prosthetic, using the material of your choice.

Finishing the Prosthetic

Once the prosthetic is milled or printed, it is ready for its final processing. Glass ceramics are finished in a crystallization oven, while zirconia restorations must be sintered in a sintering oven. These ceramics are hand-finished by characterizing, staining, glazing, and polishing the restorations.

The Finished Product

Frameworks, crowns, bridges, and other prosthetics are returned to your dental office for fitting. If further processing is required by the dental lab, the workflow moves on to the next production stage, continuing until the final product is finished.

-

Dental restorations created using a digital workflow are precision-made, keeping chairside adjustments to a minimum. A dental crown can take just 10 or 15 minutes or less to seat.

-

Industry-wide, remake percentages are approximately 4%. Using intraoral scans brings this figure down to less than 1%; this benefits both the patient and your bottom line.

A review study carried out in 2017 determined that digital scans reduce patient discomfort, are more time-efficient, and help to simplify clinical procedures. The digital workflow enables better communication with both the dental laboratory and with patients. Dental labs are more able to assist during the planning phase of complex cases, especially with dental implants cases. More planning prior to restoration will lead to a better overall outcome. It is fair to say there is a learning curve, which is the case with all new technology and techniques. There are the initial purchasing costs and ongoing maintenance of the equipment. However, adoption of digital technology is increasing and the quality of intraoral scanners is such that even complex restorative cases and full-arch treatment plans are now suitable for digital impressions.

Please be reminded that should you wish to discuss a case in more detail, our experienced technical team is here to assist you.

Click here to schedule a consultation with our technical team ›

References

http://www.straumann-cares-digital-solutions.com/content/dam/internet/xy/resources/brochurecatalogue/brochures/en/cadent-itero_---creating-the-perfect-byte/Cadent_iTero_A4_low.pdf

http://www.dentalproductsreport.com/dental/article/top-5-reasons-your-lab-loves-intraoral-scanners

https://www.firstchoicelab.com/intraoral-scanning/

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5727697/

https://thebusinessinvestor.com/digital-dentistry-market-expected-to-grow-at-a-high-rate-with-top-manufacturers-3m-espe-kavo-planmeca-group-biolase-technology-sirona/18581/